The modern market has an increasingly demanding on the working performance of transportation equipment with the rapid development of economy, what a transport equipment company should do is to stick out from the numerous conveying equipment. Screw conveyor combining all the compatible technologies, such as modern intelligent, controllable and automation, and has became the popular machine in the transportation enterprises with its high working efficiency.

Screw conveyor can be divided into horizontal screw conveyor, vertical screw conveyor, bending screw conveyor and spiral conveyor (roller conveyor) according to the different characteristics and structure of materials they transport.

Conveyor blade is the main components and wearing part of screw conveyor ,it decides the service lifetime of a whole screw conveyor. Inlet blade wear is lower, and the blade getting thinner with the movement of materials,wear volume was gradually increased, outlet blade has the maximum wear. At present, there are stretch forming, rolling molding, casting molding blades, different cross-section shape of screw conveyor obtained from different forming method . Severe abrasive wear will always cause a plant shut down. Blades made from Vautid high hardness chromium carbide overlay plate abrasion resistant plate has a low energy consumption and low repair cost, the practice proved that, it works good in the transportation of cement clinker, limestone,coal and slag.

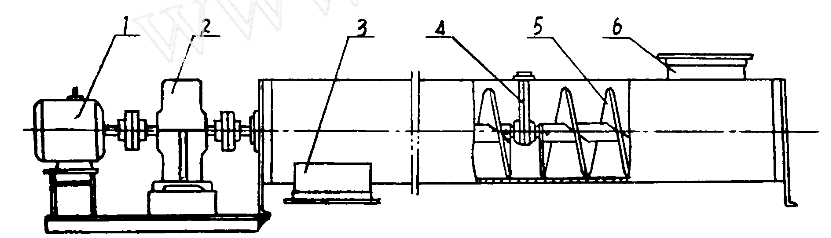

The following is the illustration of a screw conveyor

1.Electric motor

2.Decelerator

3.Outlet

4.Hanger bearing

5.Screw conveyor blade

6.Inlet