With the development of blast furnace technology and the improvement of smelting intensity, distribution system on the furnace top has been popularized and has great superiority as follows:

1.Flexible distribution, accurate spiral, sector or fixed site distribution are available according to smelting process in blast furnace chamber, help to improve the distribution and increase the gas utilization.

2.Good sealing, is conducive to enhancing top pressure

3.Convenient to maintenance, help to increase blast furnace operation rate

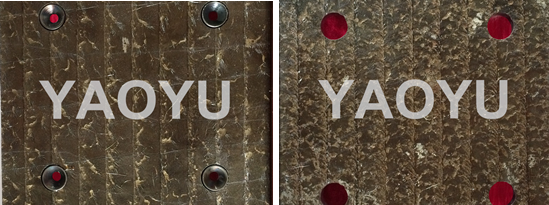

In order to improve the wear resistance and save production cost, the lining plate of distribution chute commonly use bimetallic composite wear-resistant plate, we have 5-10mm chromium carbide alloy layer welded on the ordinary steel plate. Also to make it easy to install, we usually assemble lining plate as a whole, and fix them to distribution chute using bolts.